No, this is a vacuum tube: https://en.wikipedia.org/wiki/Vacuum_tube

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is ![]()

Moderation policy: Light, mostly invisible

That was my first thought as well. I was going to be incredibly impressed if OP managed to 3D print a vacuum tube.

That or get a laugh at a 3D printed dummy vacuum tube in a $1K audiophile amp.

I read that in an Australian accent.

Though point of technically. It’s a tube. And it attaches to a vacuum.

See, and I went with Patrick. Oh pop culture. Unless, of course, you are Australian. Then, my warmest regards!

My accent is Californian by way of Minnesota.

Yes, I get weird looks when I ask for a sodah instead of pop.

But he did not call it "a tube that attaches to a vacuum."

too many words, and I'm not cool enough to just call it a "tubeythingthatattchestoavacuum."

So, Vacuum Tube makes sense.

Man, I'm old. I was wondering how in the heck you 3D printed a glass and metal vacuum tube.

Sintered glass and using solder like filament!

(Okay that might be too ugly, even by my standards….)

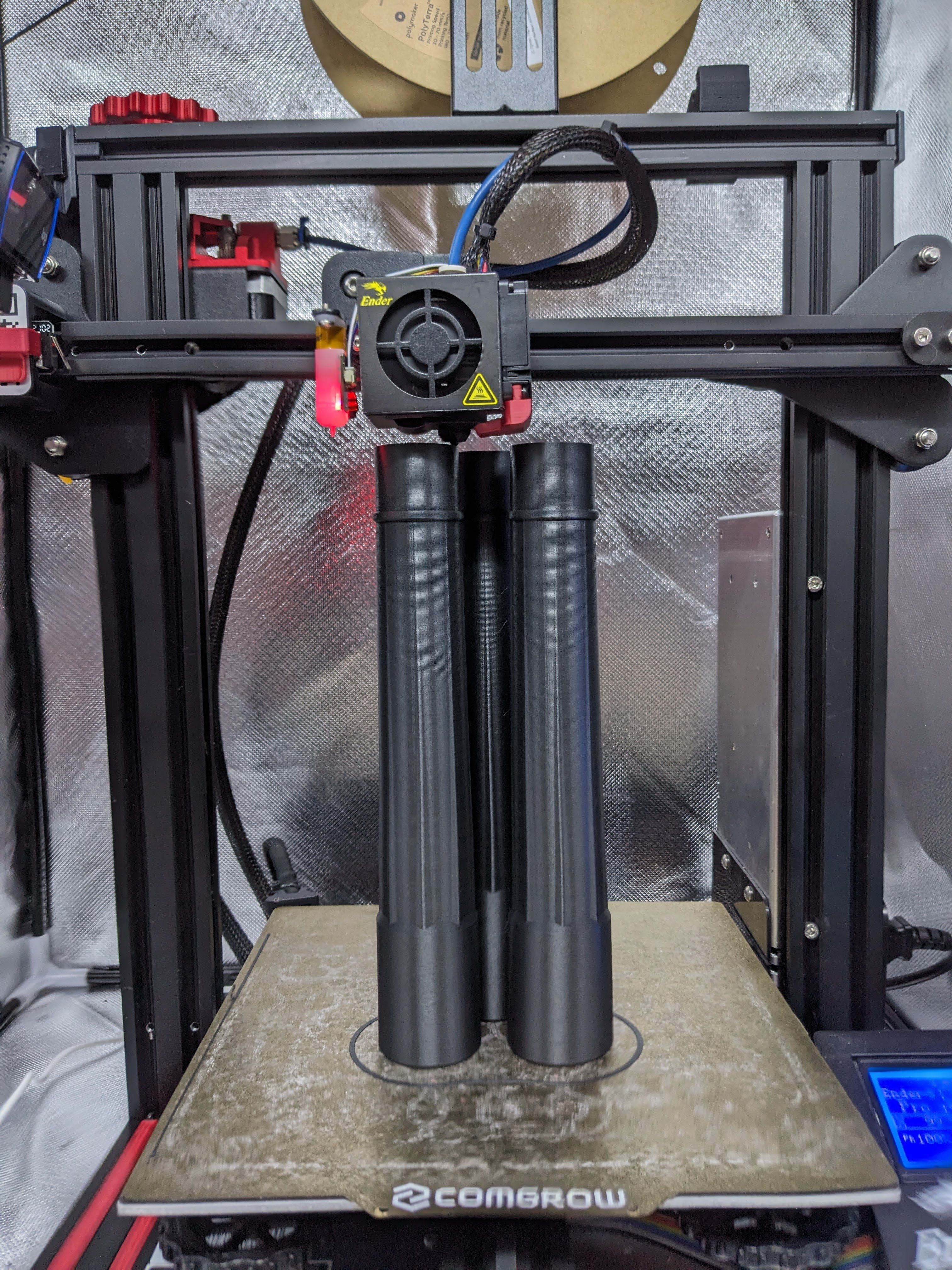

LOL yeah, not sure what else to call these, its a tube and its for a vacuum.

Why buy a $15 replacement when I can print one from $20 of filament?!

(I kid)

Very brave not to use brims on those

That is some seriously beautiful print quality. Mind sharing what settings you use?

- 0.6mm Cooper clad Nozzle

- 0.3 Layer height

- 1.2 wall thickness

- 4.0 retraction

- Use Adaptive Layers on

Filiment is Polymaker Pollyterra Charcoal Black

- 190c/50c

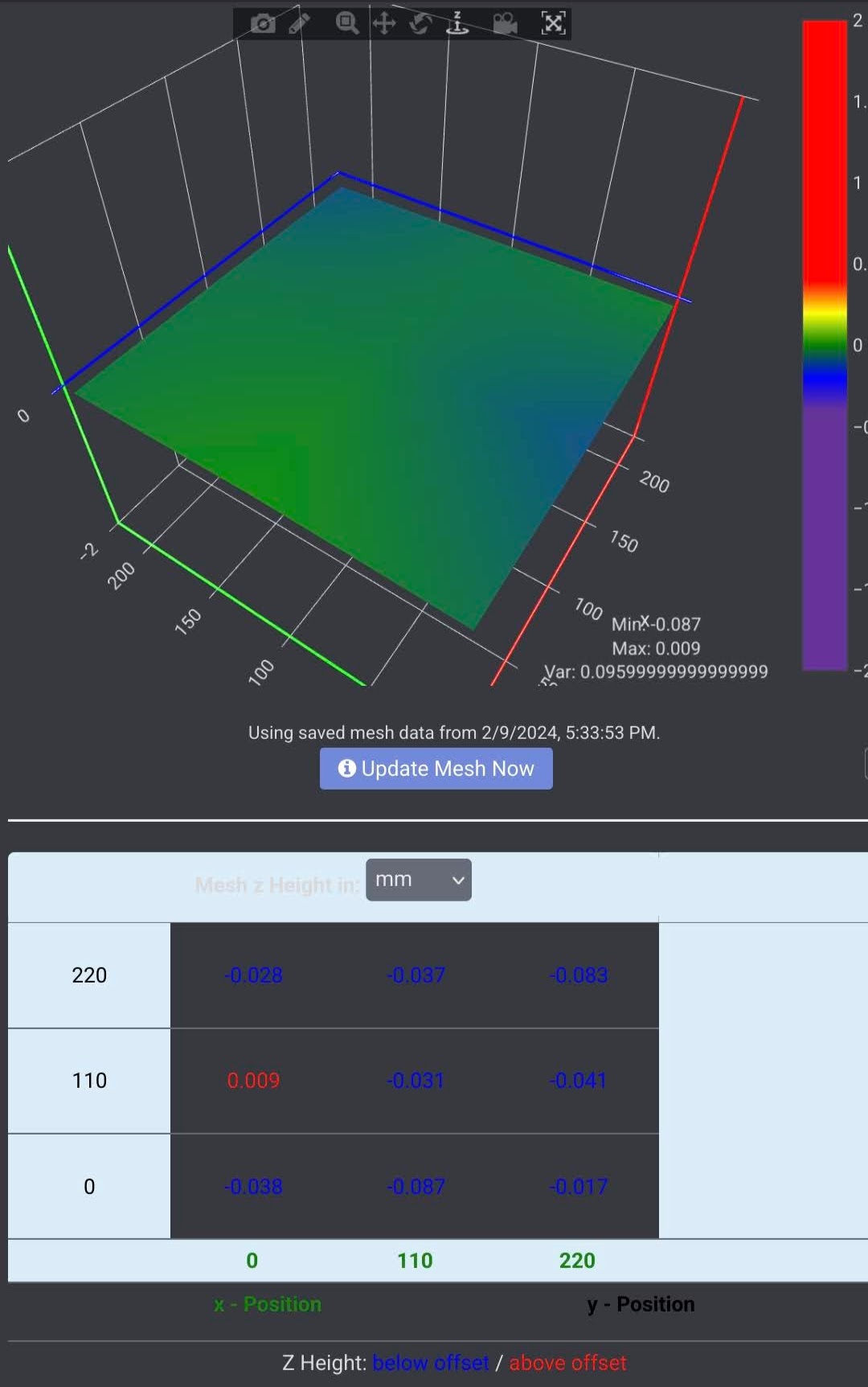

The rest comes down to tuning, print settings only account for a small part of the quality in my experience. So I put lots of time into making sure my esteps are spot on, my bed is level, I have trammed all the corners.

Did you make them better than the original, solving problems that have bugged you since you bought it?

not specifically, but because of the limitations of my printer its actually more more module so you can use a single one hand held easier.

I honestly think this is the worst use case for a 3d printer. The part isn't improved by printing. You can buy the part easily. The cost of modelling time and printing is more than the replacement. There's a decent chance the replacement part would have arrived quicker than the print took.... Sorry to be a bore, it's better than an octopus or another benchy, I'll give you that.

Excuse my ignorance, I don't know much about 3D printer material types / filament resistance, but from a few 3D printed cases for small devices I had, isn't the plastic brittle? Or the joints of layers. Especially for a long cylinder shape where force is going to be applied to. I dropped 2 cases on the floor and they broke in multiple pieces where 2 layers of filament joined. But granted, their thickness was 2-3 millimeters.

Yes normally the tube gets inserted into another tube, which is the stuck into another tube or a foot. This leaves a large moment force directly where the tube is pushed into the other tube. Most likely even with careful use, this tube will break very quickly. The layer joint is the weak spot and the type of plastic most likely isn't ideal.

Vacuum cleaner parts are made from a high impact plastic, something that's tough but a bit on the softer side. This way it can take a beating without breaking into a million pieces.

3D printing this is cool and impressive to pull off such a high and narrow print. But practically speaking it makes no sense.