this post was submitted on 16 Feb 2024

30 points (94.1% liked)

Tools

616 readers

1 users here now

Tools of all sorts are welcome. They include hand tools, power tools, automotive tools, welding, etc...

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

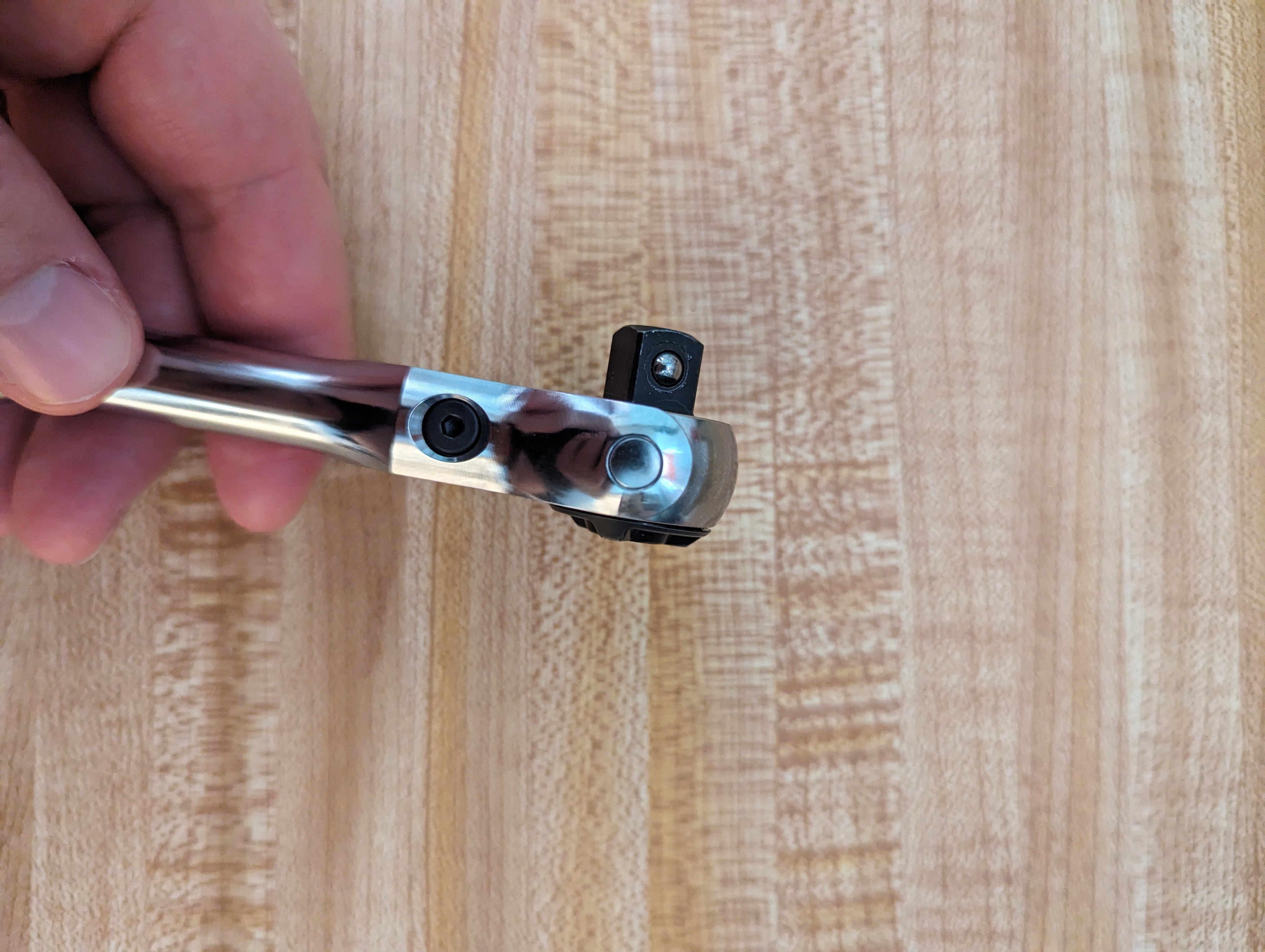

Wouldn't pay a single penny for a ratchet handle with a split down the shaft like that.

Looks like gimmicky crap to me

The one at the bottom; I can't see single reason why it needs a split shaft

The head swivels around.

That's still no reason for there to be a gap, all the way down the shaft to the handle. That's just a potential weakness

Do you actually use tools professionally or just collect them, btw?

If the latter, then yeah that's pretty cool!

The pivot point is part of the head itself so I think you need the gap to connect the head to the handle in the first place. Or no gap and hold the head in with 2 screws. Most professional brands (Snap-On, Mac, Matco) use the same gap design though. Not a professional myself, just adding to my collection lol.