this post was submitted on 16 Jan 2024

36 points (97.4% liked)

askchapo

22717 readers

1 users here now

Ask Hexbear is the place to ask and answer ~~thought-provoking~~ questions.

Rules:

-

Posts must ask a question.

-

If the question asked is serious, answer seriously.

-

Questions where you want to learn more about socialism are allowed, but questions in bad faith are not.

-

Try !feedback@hexbear.net if you're having questions about regarding moderation, site policy, the site itself, development, volunteering or the mod team.

founded 5 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

Big same. None of my friends are too into it like I am so I tend to keep it all to myself or my GF.

I saw you're into splits and staggered columnar boards above and I wanted to share my own developments to a comrade.

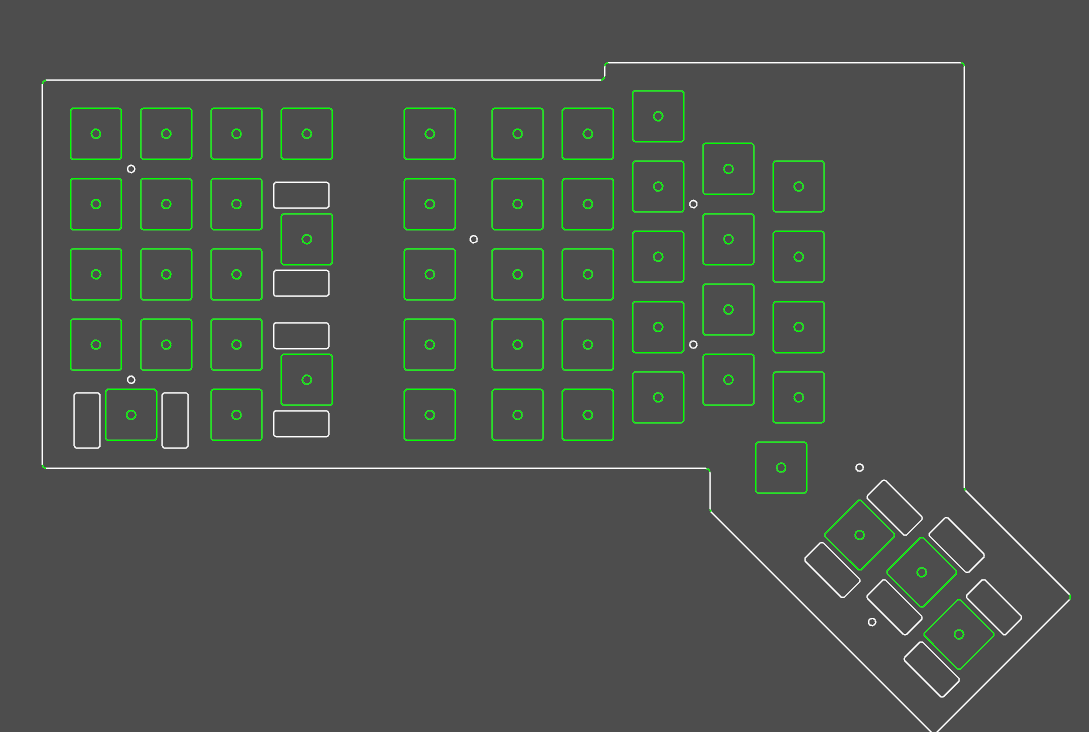

This is one that I'm still early in design on. I need to revisit the bottom part of it to fit a bigger keycap, I'm thinking either 1.25 or 1.5U. My plans are to make this one my daily driver that i take to and from work so I'm gonna put in a nice!nano for BT.

This one is one that I've already completed a hand-wired prototype for and I've just been lagging on programming it for QMK. This is the left-hand side of the split, I wanted a southpaw design with a columnar stagger and this is what i came up with. I'll probably end up having to revisit the stagger amounts later but by the time I started on the board above, I was nearly done wiring this one. The cap sizes for the modifers on the left and space/layer keys at the bottom probably have to change as well as 1.5U/2U was probably too big. My plan for this one is just to have a comfy end-game board.

My father works at a machine shop so I can easily have a fully aluminum case made for these and I'm thankful for that. I also have to work on designing actual PCBs for these because hand-wiring is a pain in the ass; it was a nice experience, but I probably will never do it again.

Yeah, the Atreus was a big inspiration for that design. I tried a planck style board for a while but I just can't do it; I need the number row.

For the bottom one I'm just having the 10 key on the left and nothing on the right. I've been looking a southpaw ortho or staggered ortho as well as a split but they all have certain compromises that I don't vibe with so I decided to just design my own.

I'm thinking the same tbh. I might end up moving one of them closer to the alphas.

For sure! I'll ping you if I remember whenever my adhd decides to cycle back to hyperfocus.

Ah yeah! This was kind of my thought with the stagger on my split design. The Mod/Q/W Columns are unstaggered for comfort when switching between WASD and typing posture. The way I did it makes sense to my hands specifically, but I think yours makes more sense in general.