Hello! It has been a week! I did some work on this! Not as much as I'd have liked because I'm sick (I believe not COVID, it's been fairly mild and if it is COVID my vax is fresh but I'm still avoiding doing a lot).

What I've been up to

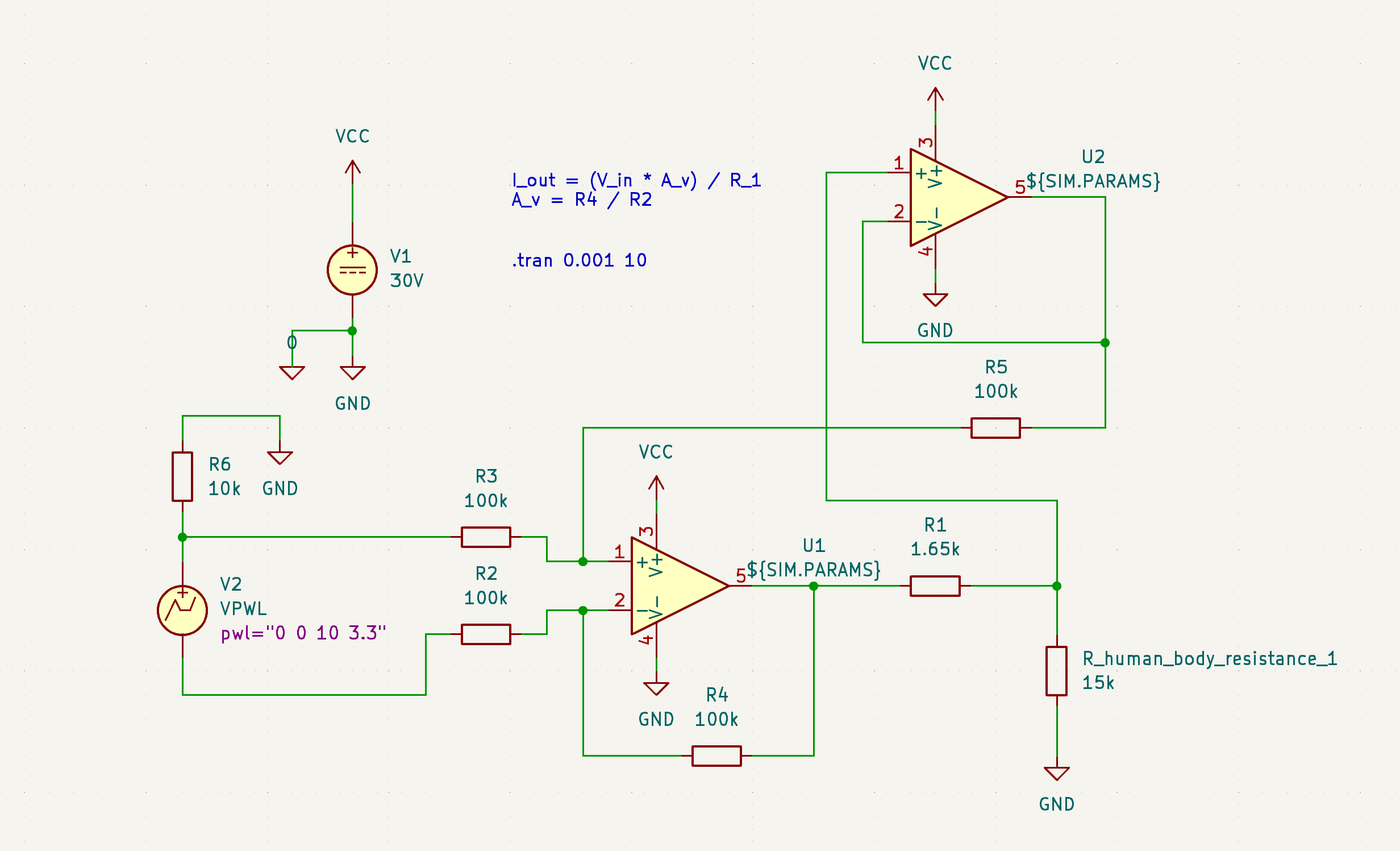

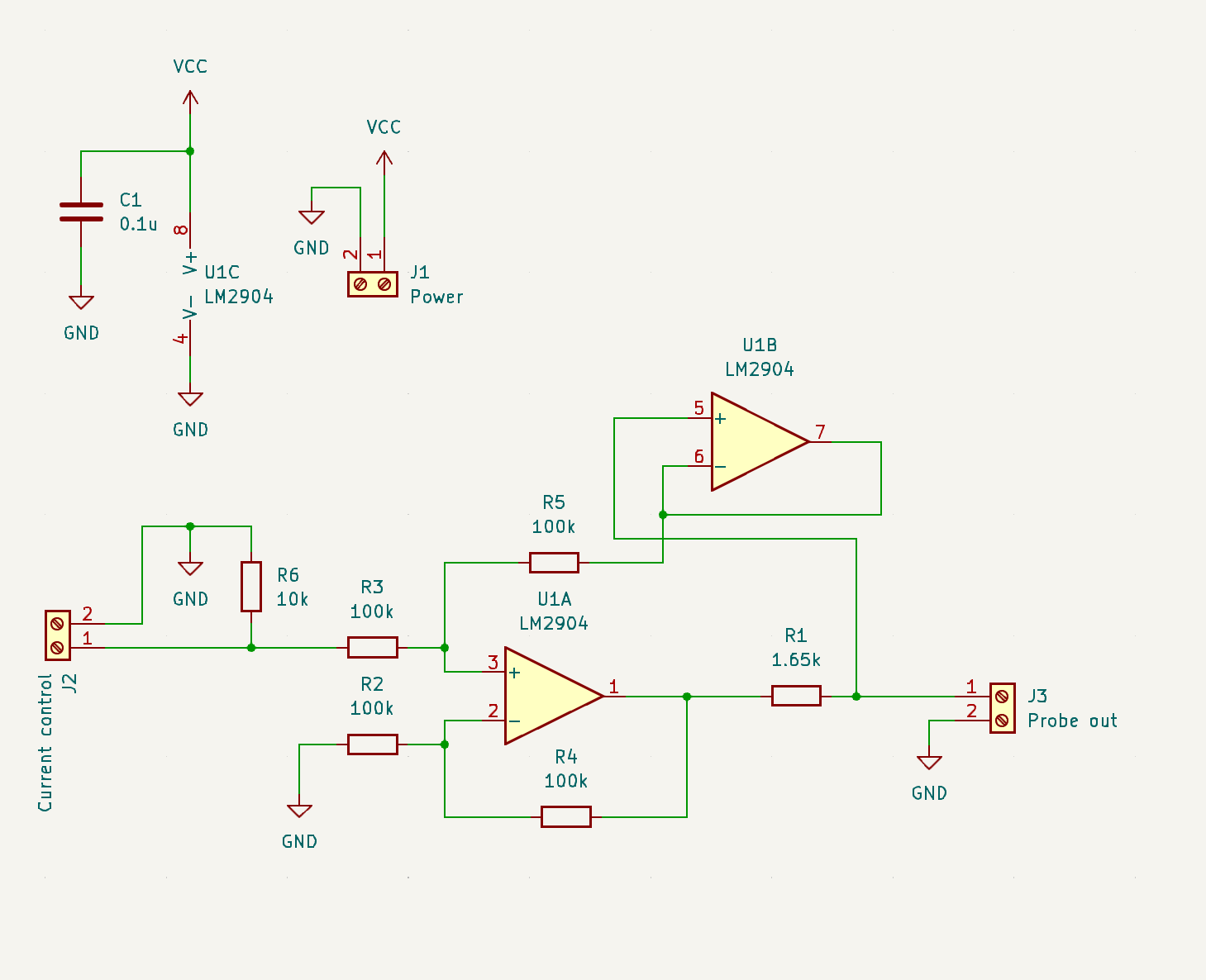

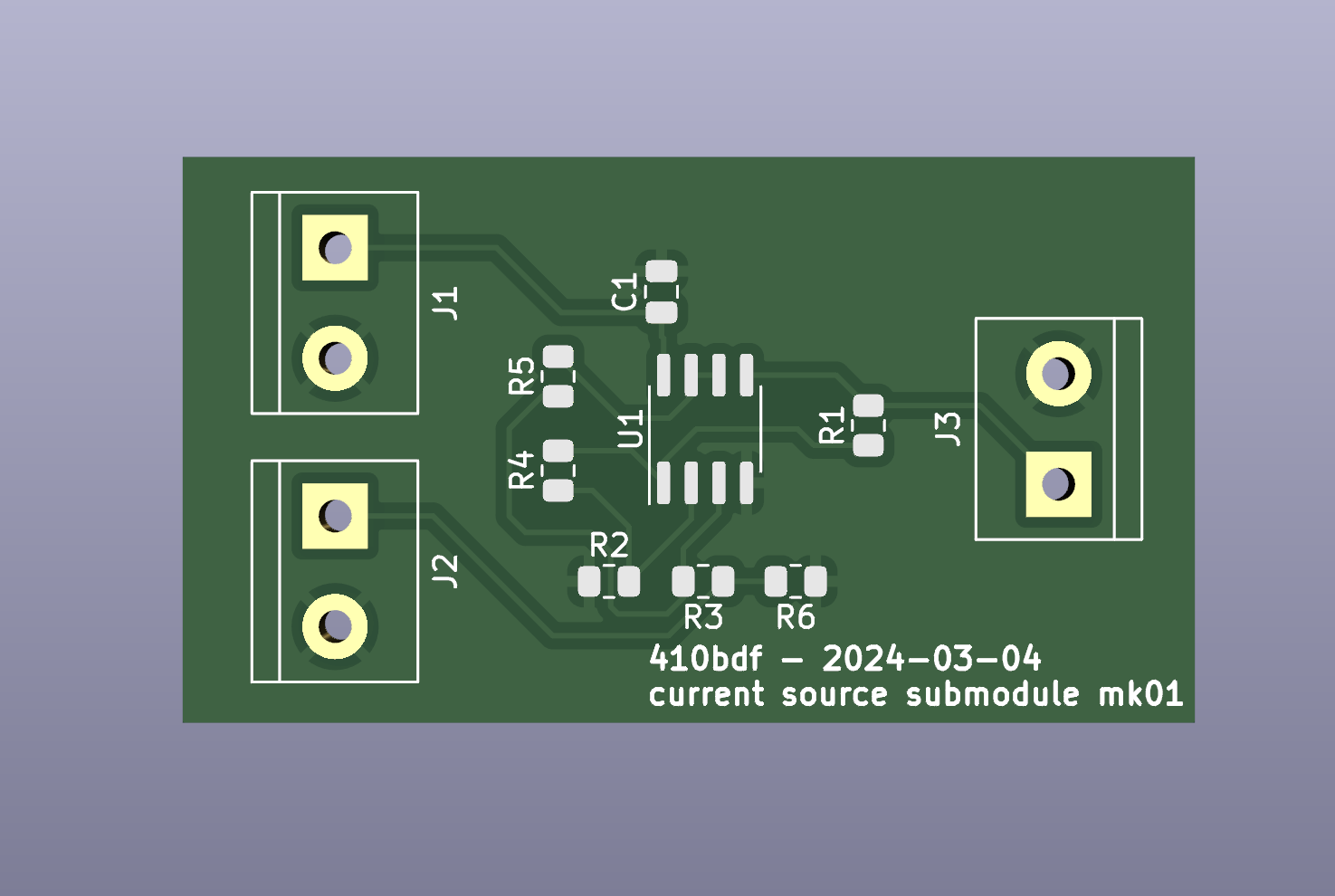

The main engineering achievement of the week was finishing drafting a schematic for the timing part of the circuit. Brief step back, in terms of development, I am breaking the first version into 3 separate pieces: the power board, the current pump frontend, and the timing board. I'm doing this so I can debug them all separately; if one of them ends up being broken and I need to wait on a new PCB or components, it doesn't block me from working on the other two. Once they all work, I will unite them all into a single PCB that will form the final version of the first release. The timing board is the most complicated of the three, and it itself breaks down further into three more parts (all on the same PCB). These are:

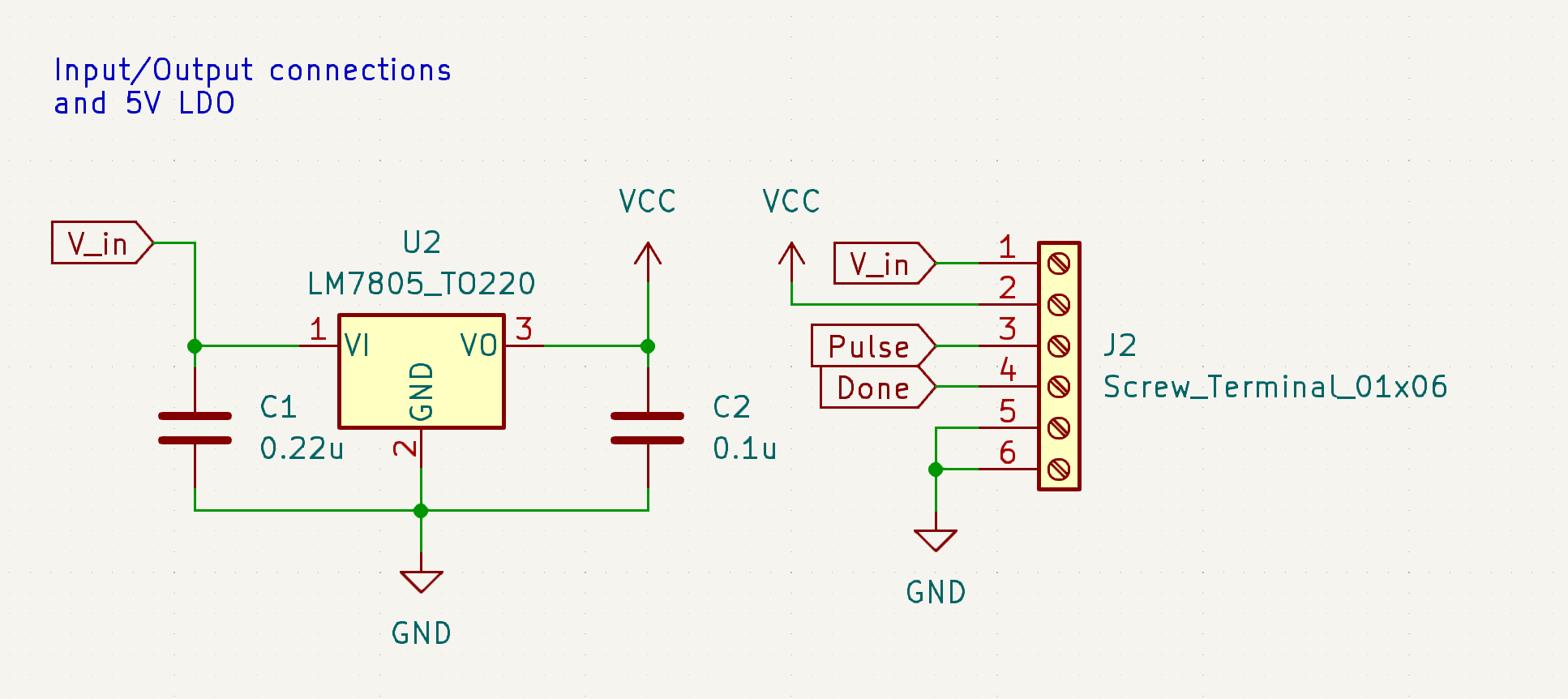

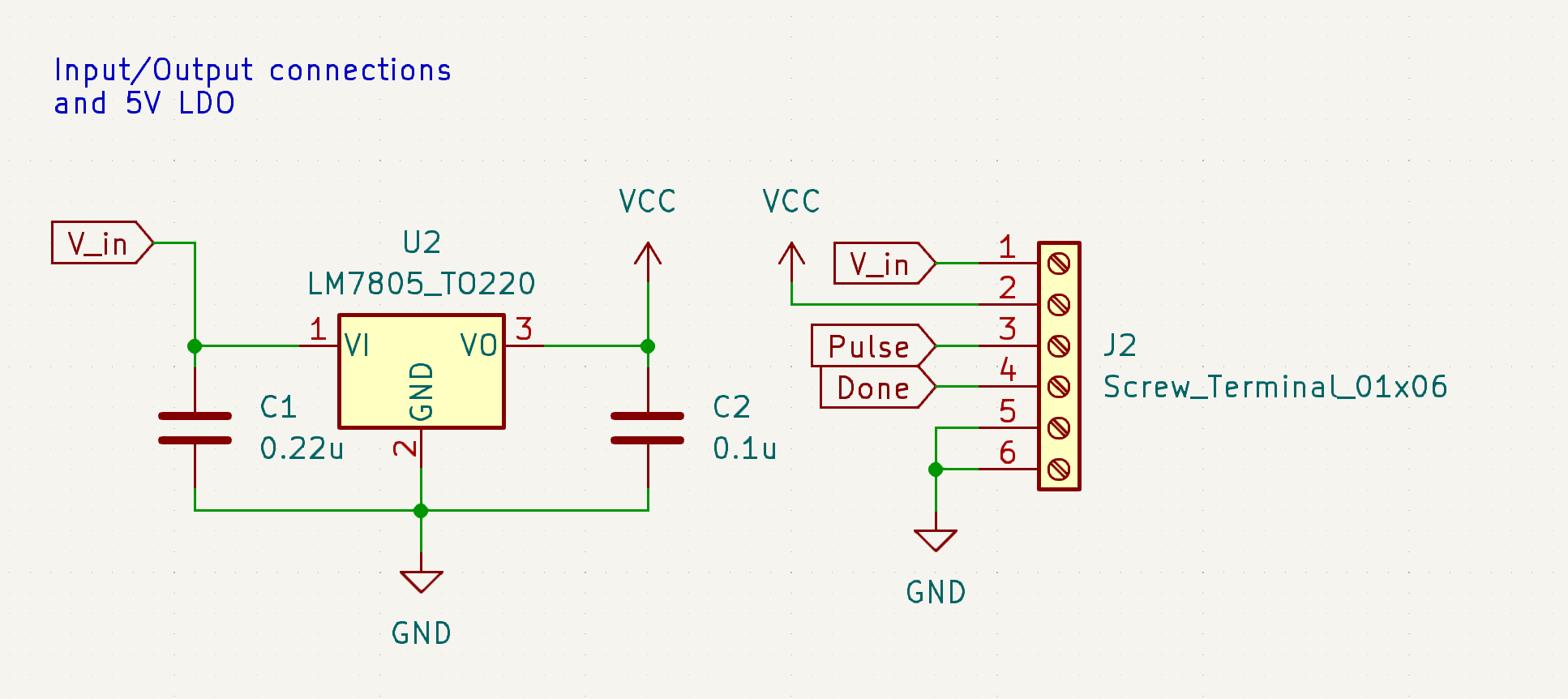

Power conditioning:

All this is is connectors to hook up inputs and outputs and a basic voltage regulator to turn the input voltage into a clean 5V to do logic circuitry with.

Pulse timing:

This is the part of the circuit that activates the current pump I drew, layed out, and ordered from my previous post. This thing has a 6.35mm jack that you plug a sustain pedal from a keyboard into (deeply proud of this idea - transfems are literally known for their audio equipment!), and on press, it will start a 5V pulse that is anywhere from 1.5 seconds to 12 seconds long, depending on the position of knob RV1. This 5V pulse will activate the current pump frontend. Notably, I am not using a 555 timer. I spent so. much. fucking. time on this fucking part of the circuit, the 555 was utimately to imprecise to feel good about including it. I was going to use a fucking crystal oscillator to keep good time at one point, and then finally I luckily found out about the LTC6993, which is an awesome 555 replacement that every amateur electronics person should get comfy with because I am never using a 555 ever again. There's still fairly sizeable error from RV1 being +/- 20% tolerance, but at least it's not stacking up from several parts, depending heavily on temperature, or any of the other problems a 555 has. This part would be a thousand times easier with a microcontroller, but at least it doesn't need to be flashed. @macerated_baby_presidents@hexbear.net you tried to warn me and I didn't listen lmao

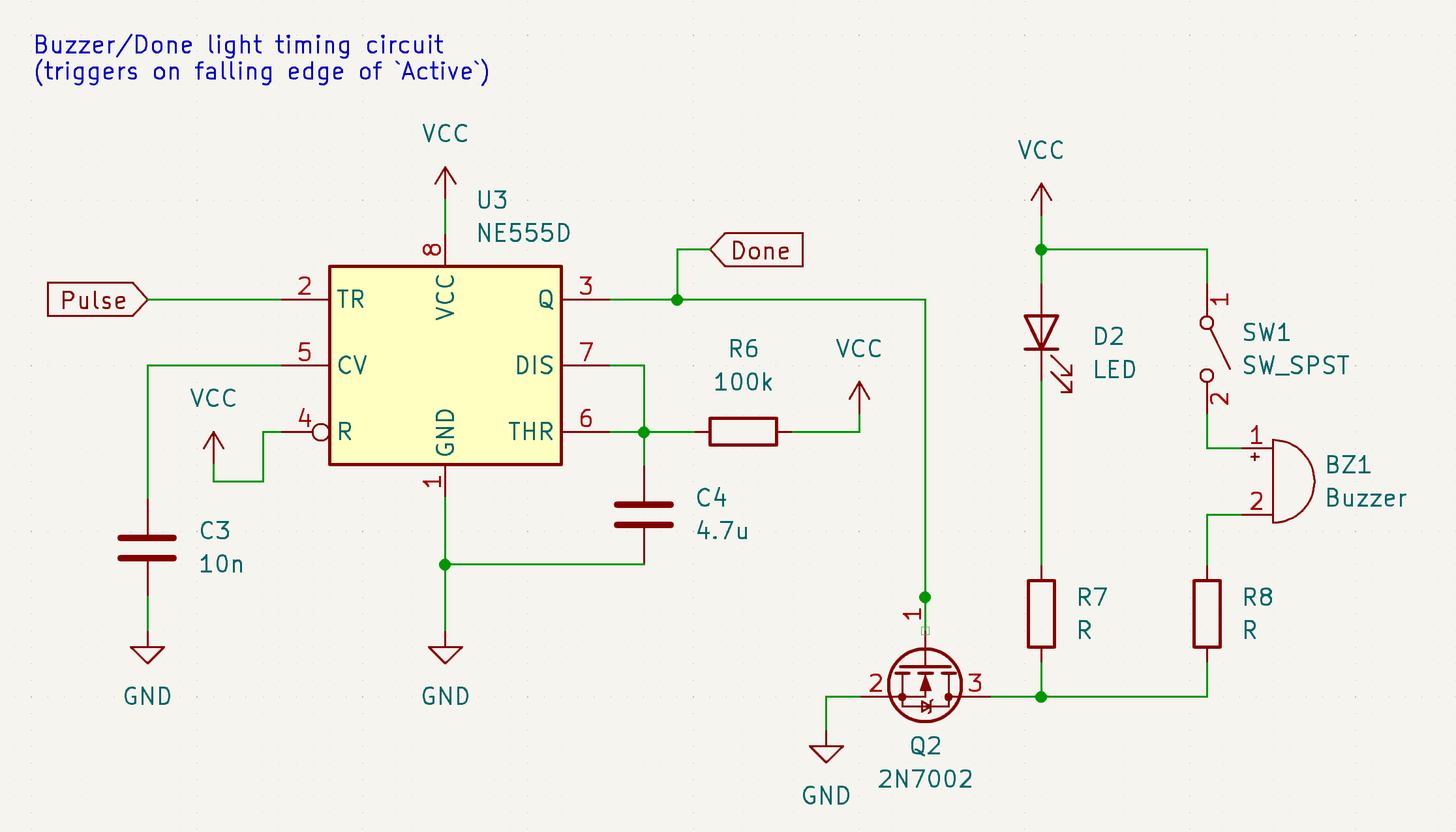

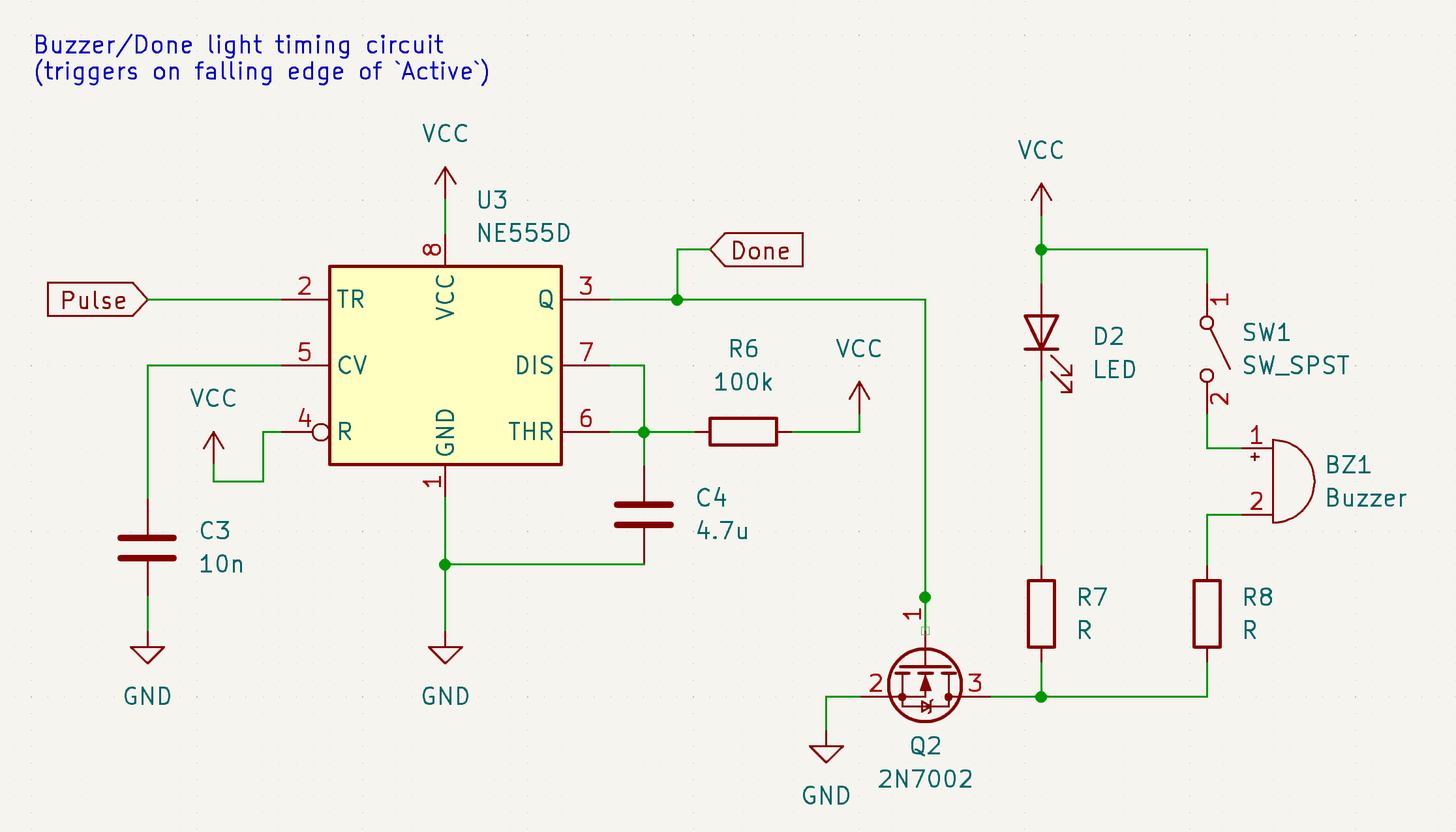

Feedback

Basically, as soon as the pulse is done, this board will turn on a little "OK!" LED and, if the switch is on, make an audible beep. This one can be a 555 timer because I don't care precisely how long the beep is. Right now it's about a half a second.

These three are all on one board. I still have to identify components to use for some of these (LEDs, buzzer, switch, 6.35mm jack, maybe more?) before I can lay out an actual PCB like I did for the current pump, but that's what I have coming up next.

That's been my week! Not a bad run if I do say so myself.

New Developments

First and foremost, I made some tough choices about how I want to plan things going forwards. I have a long and often times self-conflicting priorities list, so I wanted to come up with a road map that satisfies as many of the goals of the project as possible. So, the road map going forward from my side will be as follows:

- First, I'm going to make a push to release the first iteration, the minimum viable product to providing safe, accessible, and effective electrolysis for anyone who wants to make one, with no bells and whistles. This will have a lot of cuts (full list below) but it'll be 100% sufficient to perform electrolysis with and I'll only release it when I've confirmed that it works and it's safe. I'm going to be calling this version the Sphynx Lite.

-

- From here, once the Sphynx Lite is released, things open up for contributors to do more things for the project. This is where I'd love a couple of particularly passionate and initiated folks to get involved and start doing things like writing documentation, designing enclosures, revising the circuit to release a Sphynx Lite 2, and more. Hopefully with the board and a minimal instruction manual I'll provide for its operation and making rudimentary peripherals, we can get an ecosystem going.

- Once the Sphynx Lite is out, start work on the Sphynx Uno (Sphynx Ein? just "Sphynx"? Sphynx один? still workshopping this one a lil bit) that will roll in all the nice to haves that I left out of the Lite, while keeping a lot of things I've put effort into and would like to keep, like the current pump.

-

- With the Uno, there'll be firmware - this is where community folks will really be able to shine, for one, this is the thing that the most people expressed interest in helping with, and for two, this is the thing that allows development to be distributed, people to work on multiple things at a time, and the project to really start picking up steam.

- Once the Uno is on a clear trajectory across the finish line, that's when we can start working on the final boss, the Sphynx Wave.

Rundown of the 3 models I could ever imagine intending to make:

- Sphynx Lite: Takes 2 9V batteries. No microcontroller, no screen, likely not even a 7 segment display unless there arises a good safety argument for needing visual feedback on voltage and current, just a knob for max current, a knob for max voltage, and a knob for pulse time, with a beeper and a couple LEDs for feedback, and connectors for a foot pedal activation switch and a probe. All digital and analog electronics - no flashing required.

- Sphynx Uno: Add a microcontroller, rehash a lot of things that will benefit from having a microcontroller, like timing, input method, and whatever else comes up. Replace the 2 9V batteries with a LiPo with a proper power infrastructure, including boosting, possibly to a slightly higher voltage than the Lite, USB charging, and more.

- Sphynx Wave: Everything that the Sphynx Uno is, except instead of just the DC current pump on the frontend, add an RF power applicator circuit to the output as well (this is nerd talk for "Uno is galvanic only, Wave is galvanic, blend, or thermolysis").

(thank you to @lilypad@hexbear.net for suggesting the Sphynx name! I think I'm gonna keep it!  )

)

I've also decided that open hardware is probably the move licensing wise. It doesn't preclude me ever getting something together to start selling units, but it also keeps this a community project and allows anyone to build it as cheaply as they want to, remix it, or do anything else they'd like to themselves.

Next Up

The components to build and test the current pump are waiting on my bench. I have to build that, test it, and then honestly I can fake the rest with an Arduino and a benchtop power supply to test the output parameters and kill a test area of hairs if there's no bugs in my circuit and start the waiting game to see if they come back. I also have to lay out the timing submodule, and I have to both design and lay out the battery/power submodule. Once they all play nice tied together with wires on the bench, I'll dump all 3 designs in the same file and start weaving them together to make the Lite.

Any ways to help?

Audit my circuits above for sure, I'm being dumb and ordering a PCB before testing most of this on the bench. I'm going to add some more debugging features to the design before ordering the design, but still it'd be nice to catch as many mistakes as possible early. I also have an interesting request:

https://synopticproducts.com/collections/f-shank/products/ballet-f-and-k-shank-needle-holders?variant=40311122100305

Synoptic seems to be using a modified mechanical pencil as a probe - does anyone recognize this make of mechanical pencil? I'd love to get some and see if they lend themselves well to being made into probes. I owe you all an actual drawing of what the probe should look like and do next time too, it'd be awesome if someone could figure out how to make the probe work. If anyone feels like taking a stab at it now though, ask anything you'd like to know, but in short, all it needs to do is hold onto an F-shank needle with electrical continuity in a way that is easily replaceable and can be held like a pen. Bonus points if there's some type of shroud to cover the tip when not in use, but that's not a huge deal, it's more important that this doesn't require any advanced tools - accessibility.

Now that I've committed to a name, we can start thinking of a logo too! The added bonus of using a cat is that it's extremely reasonable to incorporate a ":3" into the logo. I would love to see suggestions if anyone's bored and looking to help! My only ask is that it should have a good monocolor representation and that it doesn't have any tiny features so I can put it on the PCB itself. If you can draw it with a sharpie, it'll work perfect.

If you have any questions, please ask below! It doesn't matter if they're technical or non-technical, it doesn't matter if you think they're basic, dumb, not worth my time, or anything else - I want people to get excited about this and I would love to take the time to communicate the inner workings of this to y'all so that everyone can be included! I can't guarantee I'll reply to everyone but I'll do my best to reply to comments that are asking something directly or I have something to add to!

Tag list is in my top level comment below, reply to that comment if you want to be added or removed. Love you. Thanks for being here. I hope I can do good by my favorite internet people. :trans-heart:

)

)