Hi! Did you bump into this post from the pin on !diy@hexbear.net? Check on my current progress on my user posts! This account is a dedicated alt for this project alone, sorting by my new posts will show the latest on this project.

Hey 🥰 I'm a transfem who's been working on something that I think might be of interest here and I'd love to share, because I believe that we can share a very mutually beneficial relationship. This post is about permanent hair removal.

I am going to use the term "transfeminine" in the following as an abridged version of "transfeminine, non-binary, and any other individual, queer or not, who would feel more confident and affirmed with less facial or body hair". This is a project for everyone.

A little bit of background on permanent hair removal:

Really, the only two options on the table are laser/IPL and electrolysis. Speaking to the former first, laser/IPL is without a doubt the most accessible of the two options, but it comes with a lot of drawbacks. For one, laser/IPL is neither permanent nor complete. This may sound like an immediate dealbreaker, but the ability to delay and diminish hair growth down to light wisps for months to years at the cost of only a handful of sessions makes it a valuable instrument in transfeminine gender affirming hair removal. The drawbacks don't end there though; another serious and deeply unfortunate drawback of laser and IPL hair removal is that they don't work on all skin tones and hair colors. The mechanism of action depends on light passing through the skin and being absorbed by hair roots (which then heats up the follicle, damaging it, hopefully, to the point that it is unable to continue growing), meaning both light skin and dark hair are requirements for eligibility. This is deeply unfortunate for all but People of Pasta.  There are other drawbacks, like an increased incidence of adverse skin reactions relative to electrolysis, but the two issues noted above make it a non-starter for black and brown folks and extra-bleached-flour crackers. These issues in mind, laser/IPL is a tool that can be relied on at times, but for trans folks, laser/IPL is a non-starter for bottom surgery preparation due to the incompleteness and temporary nature of the procedure.

There are other drawbacks, like an increased incidence of adverse skin reactions relative to electrolysis, but the two issues noted above make it a non-starter for black and brown folks and extra-bleached-flour crackers. These issues in mind, laser/IPL is a tool that can be relied on at times, but for trans folks, laser/IPL is a non-starter for bottom surgery preparation due to the incompleteness and temporary nature of the procedure.

Electrolysis is permanent, 100% complete, works on all skin tones and hair colors, and has a lower incidence of skin-related side effects. Perfect! What's the catch? Electrolysis is expensive as fuck. Where a complete course of bikini area laser or IPL may cost hundreds of dollars, the same area with electrolysis will cost thousands, sometimes as high as tens of thousands of dollars, due to the fact that unlike laser/IPL, which takes a second per exposure and can be done in areas of hundreds of hairs at a time, electrolysis must be done hair by hair, which is a lot of time to spend with a licensed cosmetologist/electrologist. Costs are similarly prohibitive for facial electrolysis, and even more wildly exorbitant for body hair removal due to the large surface area, so much that it is virtually never even discussed as an option for this. This won't do either. What is to be done?

The mechanism of action of electrolysis hair removal is to insert an electrode in the form of a fine needle down the hair shaft and pass a current through the electrode, into the hair root, and out through a return electrode elsewhere in the body. This causes an electrochemical reaction in the hair root that produces a few nano/microliters of lye, which super, definitely, for sure kills the hair. (if you know the difference between galvanic, blend, and thermolysis, you're way ahead of the class, good eye but I'll bring it up again later.)

At home electrolysis exists, but it is not easy or cheap as it currently stands. Issues with machine quality, battery consumption, and power make this an option, but an undesirable one. My hope is that we can make it easier, cheaper, and safer, by designing an option that is more robust, more available, eats through fewer batteries, operates with greater power, and is designed with constant dynamic community dialog.

One thing I didn't lose in my transition is my audacity: surely I can make a device that applies a small current through a fine needle-like electrode in a short burst, right? So I got to researching. Can I buy professional-quality electrolysis needles without a cosmetology license? (yes, I can!) Are there readily accessible schematics for precision low-amperage current sources widely available? (yes, there are!) Are there resources available not paywalled behind cosmetology/electrology programs to learn to use this thing once I have a prototype? (yes, there are!) Has anyone tried to do this before? (Yes!!! Twice!!! More than that! Reddit user /u/abbxrdy, Github user ivanbarayev, the folks on the Hairtell forms, and Andrea James at Transgender Map, I have so much love in my heart for you. Here's to hoping that your work forms the foundation to bring accessible hair removal to all.)

My goal is to make a highly buttoned up, safe, accessible, and presentable electrolysis solution for transfeminine people to use on themselves, each other and for others to use on them. I want to cut out the cosmetologists, or specifically those in the electrolysis chain that take the surplus value from transfeminine people, like salon owners and machine manufacturers. I also want to avoid reliance on sparsely available, weak, and poor quality machines, which are the current sole option for at-home electrolysis. Ultimately, the goal is to bring safe, highly effective, and accessible electrolysis hair removal to all. Currently existing solutions generally fail on at least one of these. My objectives are as follows:

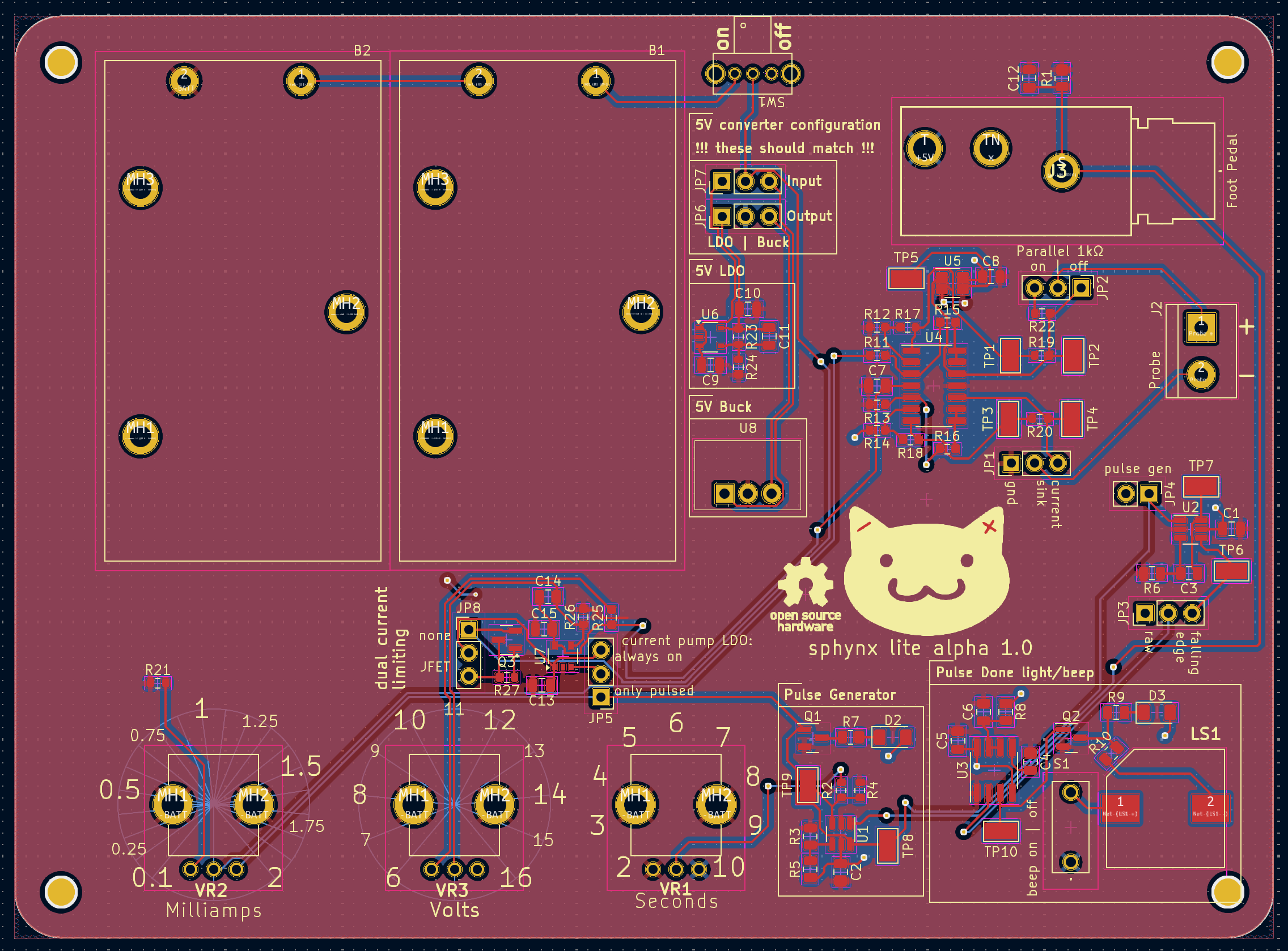

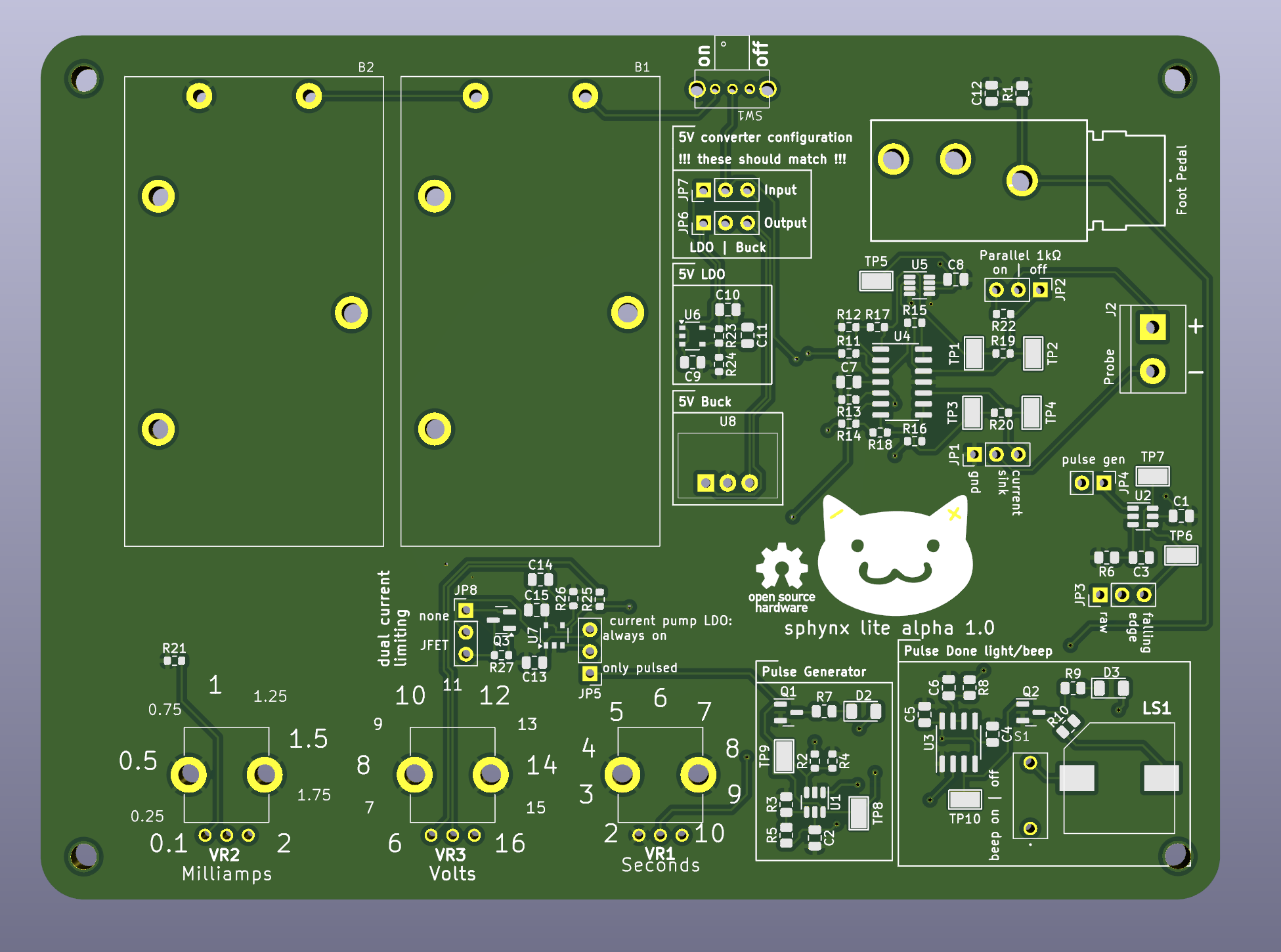

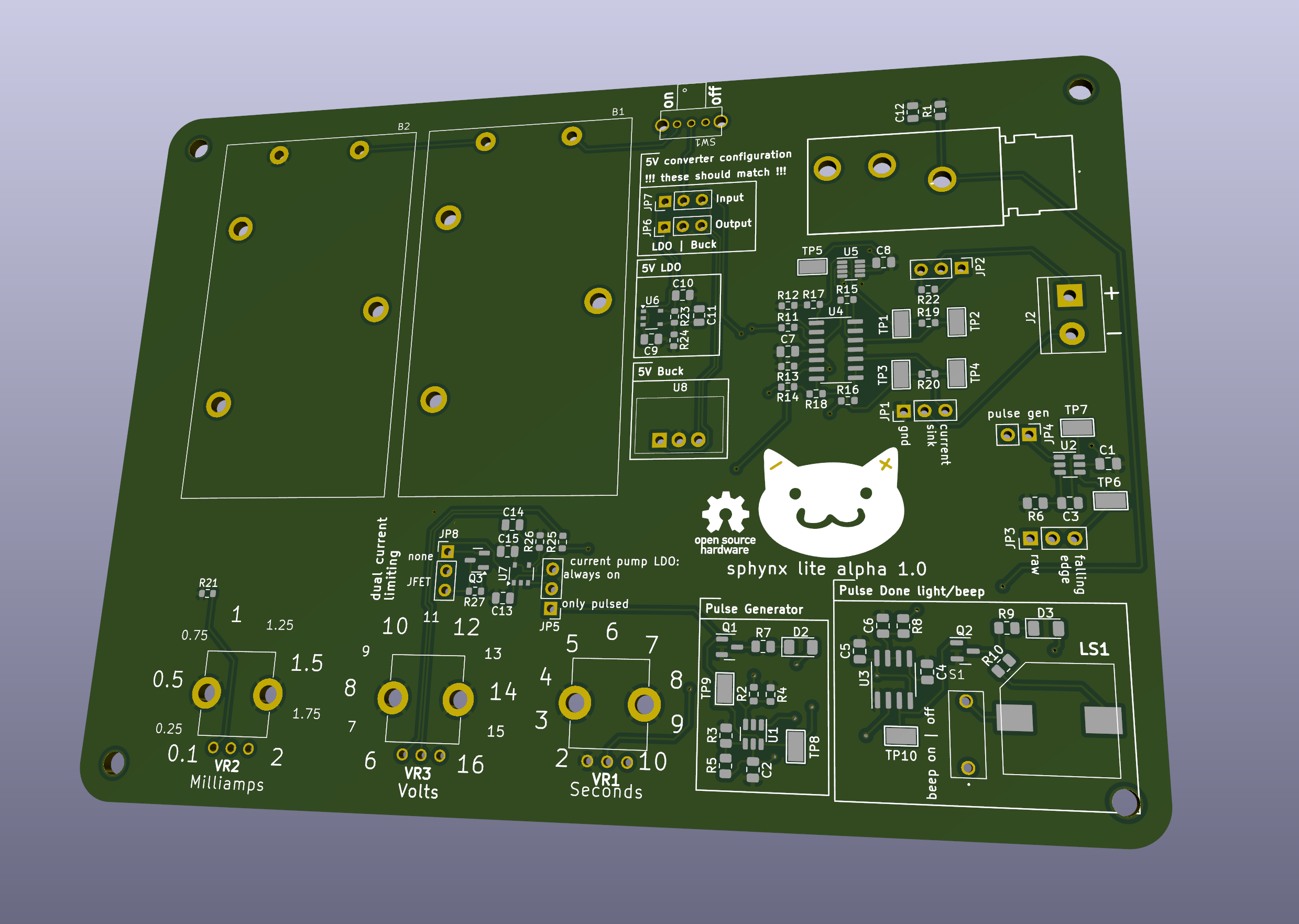

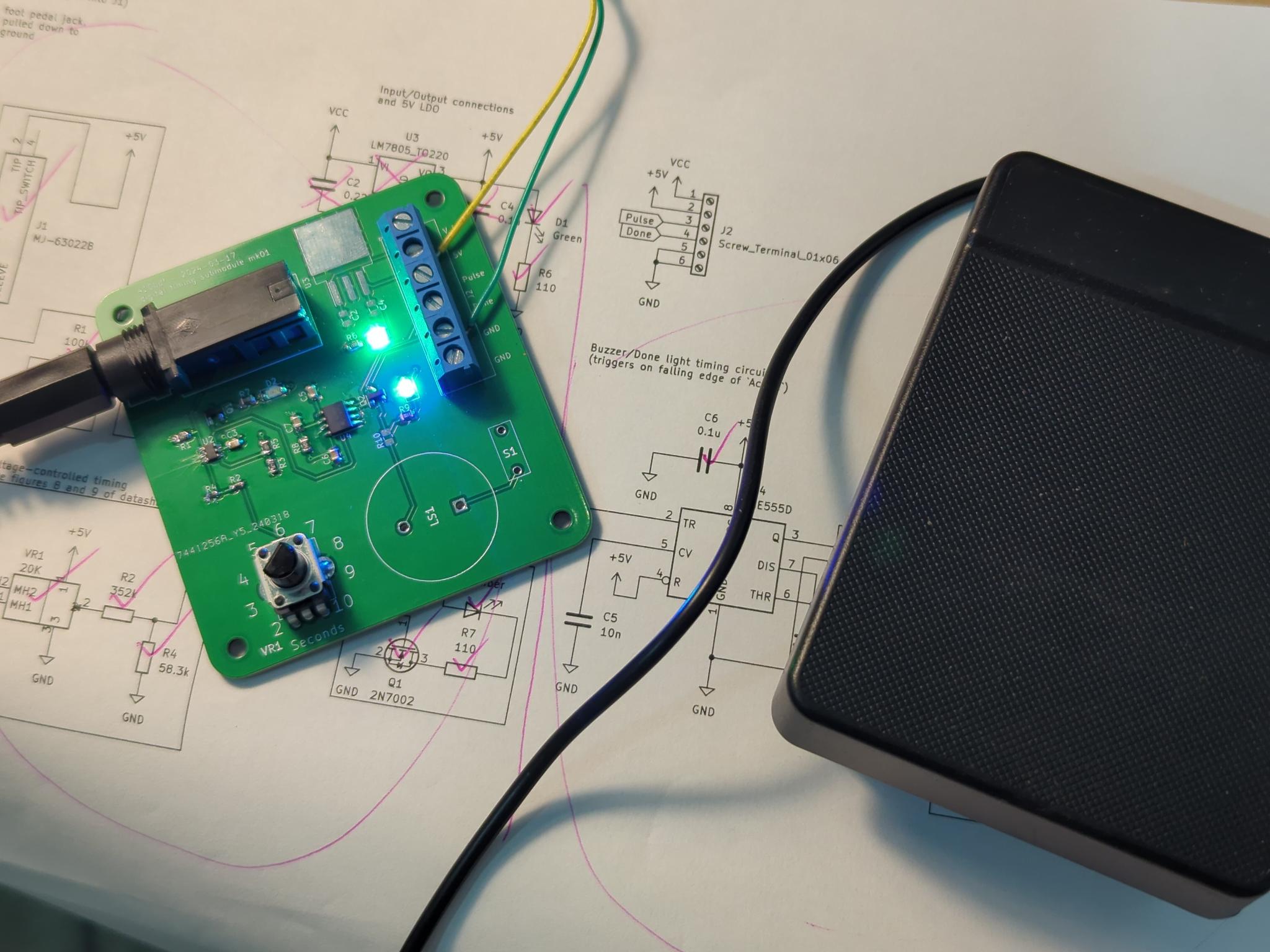

- Develop a circuit that can administer a 0.1 to 10 second pulse of current between 0 and 2 mA at a voltage between 0 and 25 V through an electrode upon each press of a button, foot pedal, or even bite switch, with no wall plug-in for safety reasons - battery power only.

- Make it into a printed circuit board that can be ordered and built out with no more than a soldering iron and YouTube tutorial level soldering skills.

- Develop a design for a probe that can hold an electrolysis needle, that can be actualized at home, without any advanced tools.

- Create a high quality and easy to follow manual for the build and usage of the device. This is missing with all current DIY solutions. This has to be something that is truly accessible to all - no electronics knowledge, wiring, debugging, multimeters, or anything else like that necessary.

- We're shooting for a budget under $100, but in general, cost is a deciding factor. It's not accessible if it's expensive.

- For now, my intention is to start with a galvanic only electrolysis machine. Blend and thermolysis produce much faster results, but I don't feel as confident working in high frequency electronics, and with galvanic being the most reliable option, despite being slower, it's the obvious pick for the 1.0 version. If this takes off, the plan is to continue with a blend or a mode-selectable version, which would really democratize electrolysis. If this works, blend electrolysis provides ten times faster hair kill time, and it's next on the menu. 👀

Here's what I'm capable of doing by myself:

- I'm an experienced multidisciplinary engineer. I have the skills to see through a basic version of this project to completion.

- I can also write a nice assembly and usage guide, I have experience in guide and technical writing for laypeople.

- I can bankroll all R&D and prototyping.

Here's what I would definitely benefit from community help on:

- I work terribly alone. I find it hard to get motivated if I don't have a team to share the work with or at least bounce ideas off of. I'm also not deeply experienced in this, and community collaboration will get rid of a lot of stumbling blocks that are probably easy avoidable. If you're experienced in analog electronics, you're the number one type of person I'm looking for, but I'd also love to work with digital/embedded folks when it comes to interface/UX time, or additionally anyone with electromechanical design experience for the probe.

- Saving the above, I still do much better with folks on the sidelines cheering me on, asking me questions, and keeping me accountable than I do alone, even if I'm working by myself.

- If you're a professional electrologist, I'd love to know what you like and don't like in a machine, what features are mandatory, what features are nice to have, and what features are pretty useless. If you have any other tips and advice, let me know!

- If you've tried DIY electrolysis before, please tell me how it went and how I can do better than whatever your most recent attempt was!

- I need help discussing the licensing. Do I want to go hardline GPL to prevent this from being picked up by manufacturers? Do I make it as open as possible with the hopes that someone can fabricate nice ones? Do I allow for manufacture with the provision that royalties be paid to some entity, which can then be redirected to some mutual aid project/charity/Maoist insurgents? Maybe even use a personal use only clause so I reserve the option to sell units as a worker's cooperative? This is all cart before the horse shit, but it's stuff that needs to get worked out before I make a github.

- What do I call it???

Going forward, I plan to post regular bi-weekly updates to keep this alive, days of the week pending Maybe Thursday and Sunday?. Look forward to the first journal entry/post tonight where I show off what I have so far! I think /c/diy is the most applicable place to post due to the comm purpose, but this initial post is getting cross-posted to /c/traaaaaaannnnnnnnnns due to the relevance in that community.

Let's stay in touch! This is an alt but I'll be checking it frequently. Thanks for being an awesome online community and I hope this can happen in a way that results in material good for my comrades.

There are other drawbacks, like an increased incidence of adverse skin reactions relative to electrolysis, but the two issues noted above make it a non-starter for black and brown folks and extra-bleached-flour crackers. These issues in mind, laser/IPL is a tool that can be relied on at times, but for trans folks, laser/IPL is a non-starter for bottom surgery preparation due to the incompleteness and temporary nature of the procedure.

There are other drawbacks, like an increased incidence of adverse skin reactions relative to electrolysis, but the two issues noted above make it a non-starter for black and brown folks and extra-bleached-flour crackers. These issues in mind, laser/IPL is a tool that can be relied on at times, but for trans folks, laser/IPL is a non-starter for bottom surgery preparation due to the incompleteness and temporary nature of the procedure.

.

.

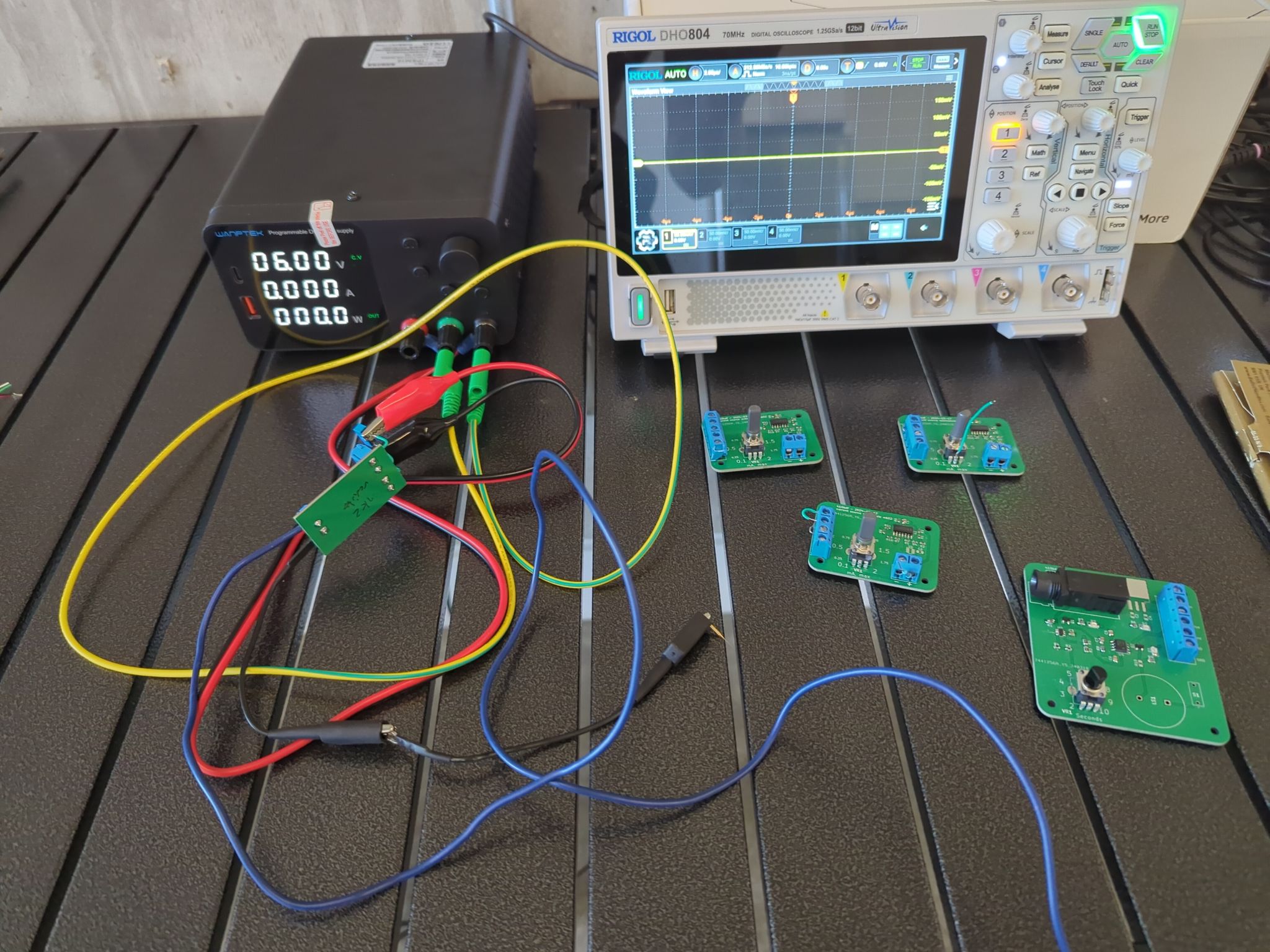

. It worked great for a few minutes and then I soldered in S1 and it stopped working.

. It worked great for a few minutes and then I soldered in S1 and it stopped working.

)

)

) and subject to change, I just needed something to test on. I was gone for over two weeks from my last post here, mainly because it was just a lot of work with nothing intermediate to report. But now it's here! This has all the working parts of the last boards merged into one, with the new additions of:

) and subject to change, I just needed something to test on. I was gone for over two weeks from my last post here, mainly because it was just a lot of work with nothing intermediate to report. But now it's here! This has all the working parts of the last boards merged into one, with the new additions of: